Key Features

High Efficiency: Our PET Strapping Machine maximizes productivity by providing top-level efficiency.

Energy Saving: Integrated energy efficiency features with modern technology help reduce operational costs.

Durability: Robust material usage and a durable design ensure long-lasting and reliable performance.

Ease of Use: User-friendly interface and automatic control systems allow operators easy utilization.

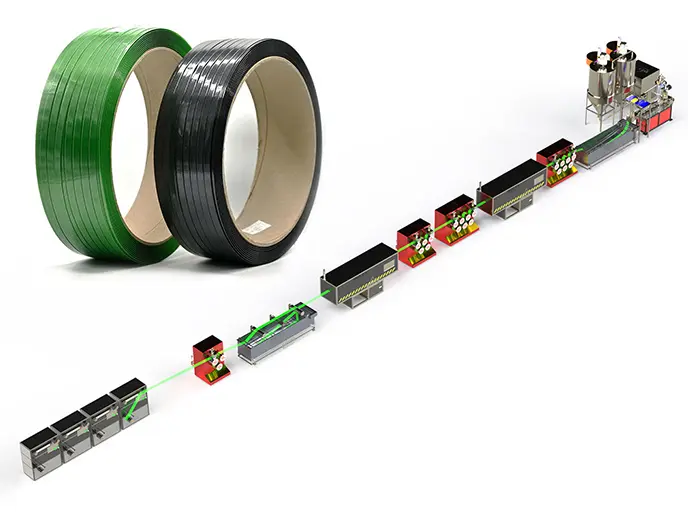

Single and Twin Screw Extrusion Technology for Customer Choice

- 100% recycled material

- PET material crystallization, drying, and moisture absorption system

- High precision of products, suitable for automatic packaging tools with belts

- Full PLC pressure closed-loop control system, synthetic rise speed, flashing filter system, stoppage of electrical changes

- Economic design option for customer choice

- Two types of control systems for customer choice in the winder: servo motor and torque motor

Advantages

High Quality: Our PET/PP Strapping Machine offers quality beyond industry standards.

Production Continuity: The machine ensures reliable performance and uninterrupted production continuity.

Environmentally Friendly: Contributes to an eco-friendly production process with energy-saving features.

Pet and PP Strapping Production Line: Innovative Solutions in the Packaging Sector

In today's evolving packaging industry, pet and PP strapping production lines stand out as innovative solutions. This article focuses on expressions such as pet strapping production line, pet strapping machine, pet strapping extrusion, PP strapping production line, PP strapping machine, and PP strapping production machine, examining the role of these innovative production lines in the packaging sector.

Pet Strapping Production Line and Machine: High Durability and Flexibility

Pet strapping production lines enable the production of strong and durable pet straps commonly used in the packaging sector. These lines involve the extrusion and shaping of high-strength pet materials using specially designed pet strapping machines. The pet strapping extrusion line offers a continuous and efficient production process, providing durable packaging solutions to the industry.

PP Strapping Production Line and Machine: Ideal for Various Packaging Applications

PP strapping production lines enable the production of polypropylene straps with a wide range of applications in the packaging sector. The PP strapping machine provides solutions that meet the needs of various industries through high-speed extrusion and shaping processes. The PP strapping production machine stands out with excellent durability, low cost, and various color options.

Composite Strapping Production Line and Machine: Multiple Material Advantages

Composite strapping production lines combine the advantages of materials such as pet and PP, offering more durable and flexible packaging solutions. The composite strapping machine is designed to meet various demands in the packaging sector by bringing different material layers together. These straps excel with high tensile strength and impact resistance.

Strapping Production Line for Packaging: Reliable and Fast Packaging Solutions

Packaging strapping production lines specialize in producing durable packaging solutions, especially in the logistics and shipping industries. The packaging strapping machine responds to high-volume packaging needs with fast and automatic production processes.

Briquette Packaging Strapping Production Line: Key to Sustainable Packaging

Briquette packaging strapping production lines focus on sustainable packaging applications, often producing straps from recycled materials. These lines offer an ideal option for businesses looking to reduce the environmental impact of the packaging industry.

Strapping Production Line Prices: Balancing Value and Investment

Strapping production line prices vary based on technology, capacity, and features. Prices for pet strapping production lines, PP strapping production lines, and other factors should be carefully evaluated based on the budget and needs of businesses.

For detailed information, click the "Get a Quote" button or contact us through our phone numbers.