Delta Plastik: Expertise in Hose Production Machines

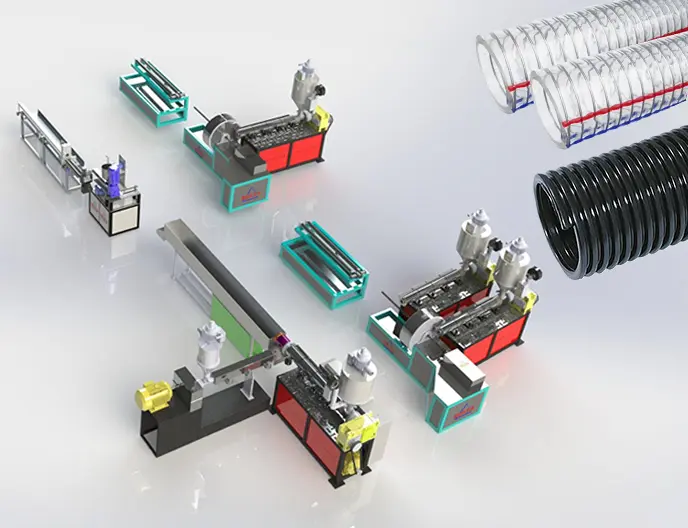

Our company specializes in research, design, and production of plastic hose production lines, including plastic soft hose production lines, flexible hose production lines, spiral hose production lines, steel wire reinforced hose production lines, and various specially designed hose production lines. In simple terms, if you have a sample, we can create a custom machine for you.

For years, leading manufacturers of electric vacuum cleaner hoses in Turkey have been using our machines.

We can produce the following hose machines:

- Siphon hose production line

- Cable protection corrugation hose production line

- Air conditioner water discharge hose production line

- Air conditioner insulation hose production line

- Washing machine water discharge production line

- Electric vacuum cleaner spiral hose production line

- Wire-reinforced electric vacuum cleaner production line

- Swimming pool hose production line

- Plastic flexible hose extrusion production line

- Air/water/oil/material transfer hose production line

- Hookah hose production line

- Medical hose production line

- Metal wire spiral-reinforced hose production line

- Dual-color, dual-layer spiral hose production line

Machine Details

- High Speed

- High-Quality Machine Components

- Zero Waste Raw Material

- Easy Operation and Use

- PLC Touch Control Screen

- Dual Reel Formation

- Servo Motor Cutting

- Stable Operation

- Warranty

We have combined German and Italian technology; we are a leader in electric vacuum cleaner hose machines in Turkey.

- 100% PLC control; no need for workers once the machine starts operating.

- Maximum production speed of 6 meters per minute.

- Hose bending test passed 75,000 times successfully, hanging test passed 75,000 times successfully.

- Easy machine startup; can start in 10 minutes with no waste material, high durability, high flexibility.

- Diameter (ID): 28mm-75mm; easily adjustable during hose production.

- Electric cable can pass through the hose during production.

- Servo motor cutting completes the cut in 0.02 seconds.

After-Sales Services

- Our technicians come to your factory for machine installation and operation.

- We provide raw material formation.

- We provide training to your factory workers.

We are not intermediaries; we are manufacturers! Delta Plastik Extrusion Machines has been a pioneering company in the Turkish plastic industry since 1998. Recognized plastic manufacturing companies and brands in Turkey have been using our machines for years.

While our headquarters are in Istanbul Zeytinburnu, our production activities take place in our 3000m² factory in Qingdao, China. As a reputable Turkish company manufacturing machines in China, we have become a well-known brand in the plastic industry.

With over 25 years of experience in plastic extrusion machines, we are experts in the field. If you have a sample, your machine is with us! Our machines are our own production and come with a warranty. The machine's video is attached.

For sample inspection and detailed information, please contact us.

Hose Production Lines: Intersection of Diversity and Innovation

Hoses are flexible and durable materials widely used in many industries. The wide range of applications for hoses has led to the emergence of specialized hose production lines that can produce hoses with various properties and purposes. In this article, we will focus on various hose production lines, including plastic hose production lines, siphon hose production lines, cable protection corrugation hose production lines, air conditioner water discharge hose production lines, and a range of specially designed hose production lines.

Hose Production Lines: Tailored Solutions for Various Sectors

Hose production lines comprise specially designed machines tailored to industrial needs. These lines have a broad technical spectrum to produce various types of hoses. Here are some specific applications of these hose production lines:

- Siphon Hose Production Line: Focuses on flexibility and waterproof properties for siphon hoses used in areas like bathrooms and sinks.

- Cable Protection Corrugation Hose Production Line: Produces flexible hoses resistant to impacts for protecting electrical cables.

- Air Conditioner Water Discharge Hose Production Line: Optimizes durability and water conduction properties for hoses used in air conditioning systems.

- Air Conditioner Insulation Hose Production Line: Designs hoses for air conditioning systems with insulation properties.

- Washing Machine Water Discharge Production Line: Produces hoses for washing machines in various sizes and specifications.

- Electric Vacuum Cleaner Spiral Hose Production Line: Combines flexibility and durability for vacuum cleaner hoses with a spiral structure.

- Wire-Reinforced Electric Vacuum Cleaner Production Line: Manufactures hoses with wire reinforcement for added strength.

- Swimming Pool Hose Production Line: Develops hoses suitable for swimming pool applications.

- Plastic Flexible Hose Extrusion Production Line: Designed for general-purpose plastic flexible hoses for various industries.

- Air/Water/Oil/Material Transfer Hose Production Line: Offers versatile hoses for material transfer in air, water, or oil applications.

- Hookah Hose Production Line: Specialized production for hookah hoses.

- Medical Hose Production Line: Creates hoses suitable for medical applications.

- Metal Wire Spiral-Reinforced Hose Production Line: Produces hoses with metal wire reinforcement for increased strength.

- Dual-Color, Dual-Layer Spiral Hose Production Line: Designs hoses with dual-color and dual-layer features for specific applications.

Innovation in Hose Production Lines: Special Applications

Hose production lines continually adapt to advancing technology, offering various innovative solutions for special applications. Specialized lines for wire-reinforced hoses, electric vacuum cleaner hose production, and drip irrigation hose production are designed to meet industrial needs and produce hoses suitable for various sectors.

Hose Machine Prices and Investment Evaluation

Hose machine prices vary based on technical specifications, production capacity, and applications. Investors should carefully examine the long-term returns of the investment in terms of production capacity, efficiency, and product quality when evaluating hose production line prices.

Hose Production Line Prices: Balance of Variety and Quality

Prices for hose production lines vary considering the technical features of machines designed for a wide product range and specific applications. However, the flexibility and high efficiency of a quality hose production line, catering to various sectors, are essential advantages for investors.

Hose Production Facilities: Compliance with Environmental and Quality Standards

Hose production facilities are carefully designed with a focus on using environmentally friendly materials and energy efficiency. Compliance with environmental and quality standards is a top factor in the design of modern hose production lines.

Shape the Future with Hose Production Lines

Hose production lines, bringing together diversity and innovation, offer flexible and durable hose solutions tailored to industrial needs. Whether it's a plastic hose production line, siphon hose production line, cable protection corrugation hose production line, or a range of specialized application lines, hose production lines are developed to meet industrial demands. In line with technological and engineering advancements, hose production lines present the key to an environmentally friendly and sustainable future. Investments in hose production line prices contribute positively to industrial processes by enhancing the quality and durability of hoses used in various sectors.

For detailed information, click the "Get a Quote" button or contact us through our phone numbers.