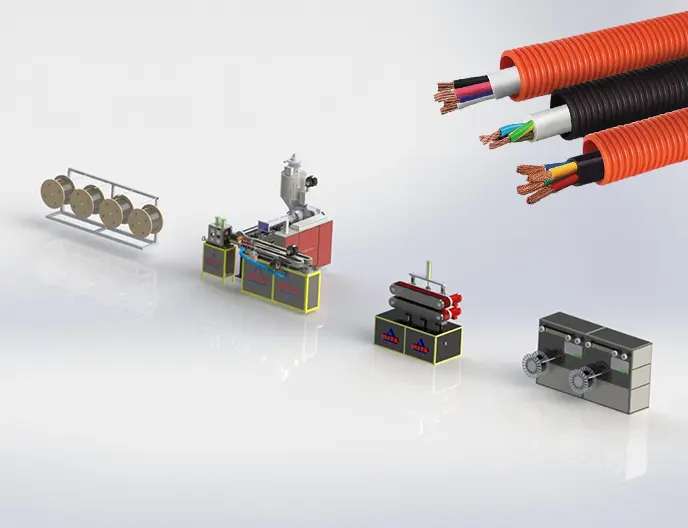

The production line for a conduit with an electrical cable passing through it is typically manufactured using an extruder machine. This line essentially enables the production of pipes made from thermoplastic materials.

The fundamental machine forming the basis of the production line is typically an extruder. The extruder shapes granules or powder of thermoplastic materials by melting them into a pipe. The material used is often plastic polymers such as polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP).

Immediately after exiting the machine, the pipe is shaped and calibrated to have a specific diameter. Then, a cooling unit helps the pipe harden.

The cooled pipe is passed through a drawing machine. This machine pulls a specific length of the pipe and then cuts it. This step ensures that the produced pipe is divided into pieces of the desired length.

Pipes with an electrical cable passing through them are often produced in a spiral form. This spiral shape is created by bending the straight pipe coming out of the extruder in a specific way. This process provides a suitable passage for the cable inside.

As part of the pipe production line, there may be a special assembly unit for cable passage. This unit ensures the proper placement of the electrical cable inside the spiral pipe.

The produced pipe can be covered with an additional insulation layer. This provides additional security to protect the electrical cable from external factors.

A spiral pipe production line with a cable passing through it, as described, facilitates the protection and organization of electrical cables for various applications, including industrial and household uses.