Profil Extrusion: Definition, Advantages, and Industrial Applications

Profile extrusion stands out as an indispensable element in modern industrial designs and innovations. This unique plastic shaping method plays a leading role in the production of various products used in various industries. Let's take a closer look at the fascinating world of profile extrusion.

What is Profile Extrusion?

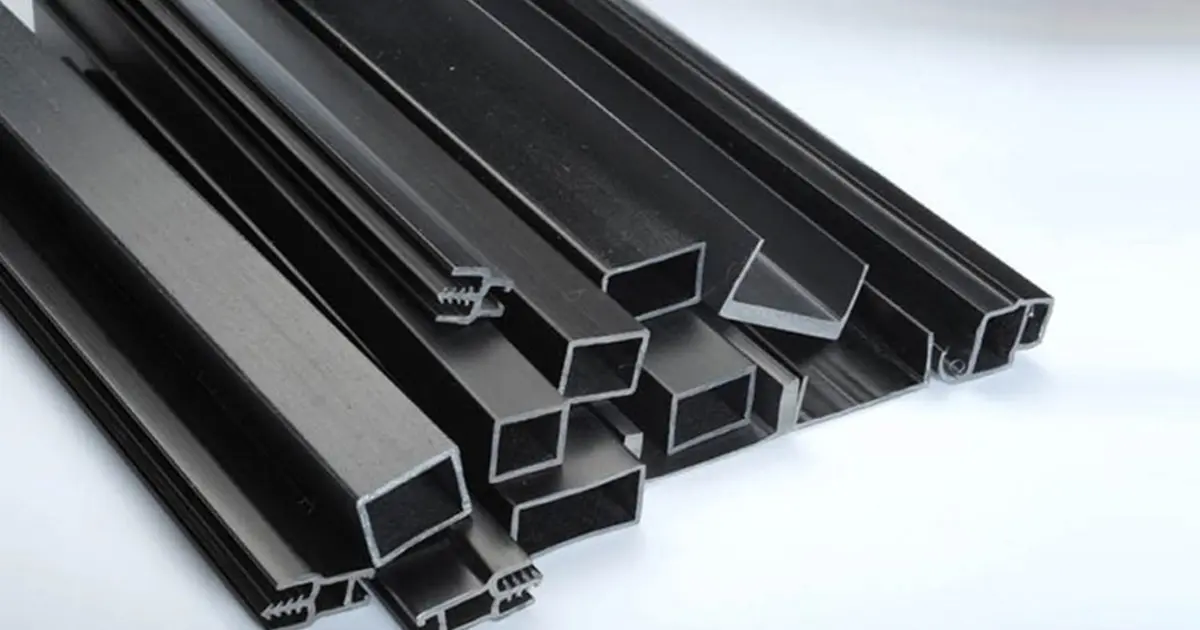

Profile extrusion is a manufacturing process that involves melting and shaping thermoplastic materials through specially designed molds. This method is particularly used in the production of products in long and continuous forms, often for the manufacturing of pipes, sheets, profiles, and various plastic structural elements.

Advantages of Profile Extrusion:

- Excellent Design Flexibility: Profile extrusion allows for the easy realization of complex and custom designs, providing product designers with a broad creative space.

- Material Variety: Profile extrusion enables the use of various thermoplastic materials, allowing the production of products tailored to the needs of different industries.

- High Efficiency and Low Cost: The continuous production process reduces costs and ensures high-volume production, offering an effective solution on an industrial scale.

Applications of Profile Extrusion in Industries:

- Construction: Profile extrusion is widely used in the production of construction materials such as door and window profiles.

- Automotive: Profile extrusion is frequently preferred for the production of automotive parts like interior and exterior trim elements, pipes, and hoses.

- Electrical and Electronic: Profile extrusion is used in the production of electrical cable channels, connecting elements, and other electronic components.

The Future of Profile Extrusion:

Profile extrusion, with its various advantages in industrial design and manufacturing, will continue to be significant in the future. This innovative plastic shaping method will play an indispensable role by adapting to the continually evolving needs of the industry, meeting the aesthetic and functional requirements of products. Profile extrusion continues to push boundaries in the plastic world, expanding the limits of design.