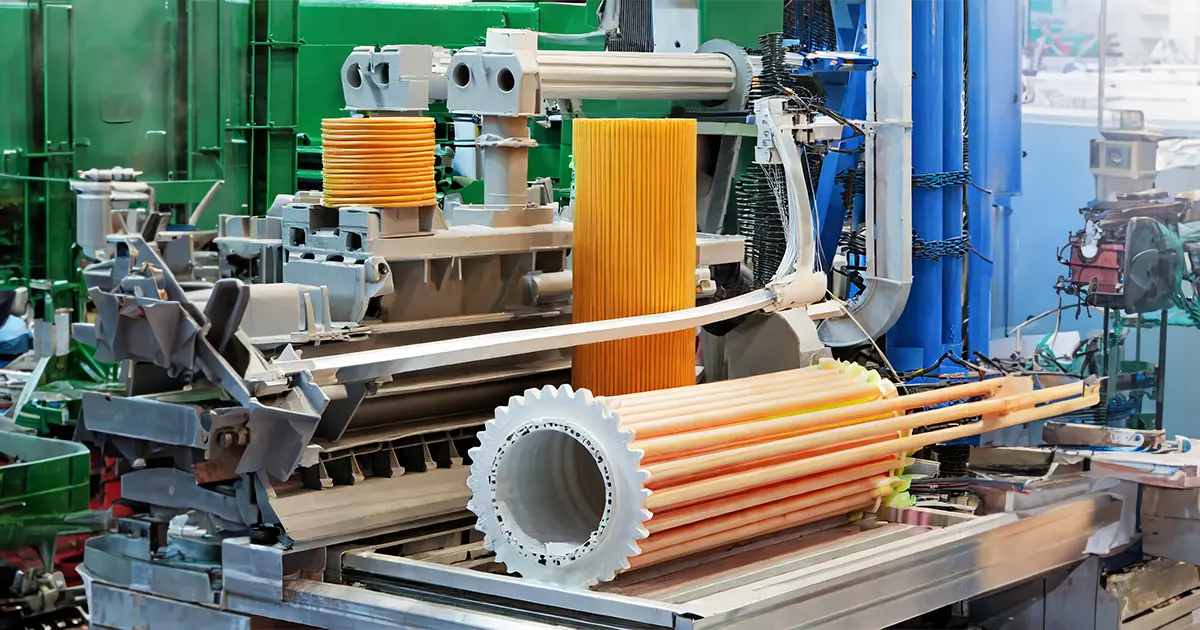

Plastic extrusion is a fundamental process for shaping and manufacturing plastic materials. In this article, we will explain the basic principles of plastic extrusion technology to help everyone involved in plastic production better understand this process.

What is Extrusion and How Does It Work?

- Definition and basic principles of the extrusion process.

- Key components and operating principles of the extrusion machine.

- Material flow, heat treatment, and extrusion dies.

Different Types of Extrusion and Applications

- Types of single-screw and twin-screw extrusion machines and their applications.

- Various extrusion applications such as pipe, profile, film, wire, and cable production.

- The role of extrusion in different industries like the plastic packaging industry, automotive sector, construction, and more.

The Extrusion Process and Parameters

- Temperature control and the material melting process.

- The role of screw design in material mixing and conversion.

- The impact of feed rate, output speed, and die design on the properties of extruded products.

Quality Control and Troubleshooting

- Quality control processes and monitoring the output.

- Common issues during extrusion and how to troubleshoot them.

- The influence of material selection and process parameters on product quality.

Innovations in Extrusion Technology

- The importance of state-of-the-art extrusion machines and equipment.

- Innovations in digital controls, automation, and energy efficiency.

- The future of plastic extrusion technology and potential applications.